We control quality from the source: the grape.

Our process begins in the vineyard, combining the production of must in our own facilities with the purchase of raw materials from local cooperatives, under a mixed model that guarantees proximity and quality.

Nowadays, everyone demands transparency in the supply chain: consumers, regulatory bodies, and the manufacturing and distribution companies themselves, which must provide detailed information about the products they offer. Given this scenario, in which concentrated grape juice can have different origins and processing methods, it is essential that juice suppliers accurately provide the origin and transformation processes of each batch. This not only guarantees the safety and quality of concentrated grape juice for the industry, but also allows industrial customers to offer a safe, high-quality food product to the end consumer, which in turn strengthens their competitive position in the market.

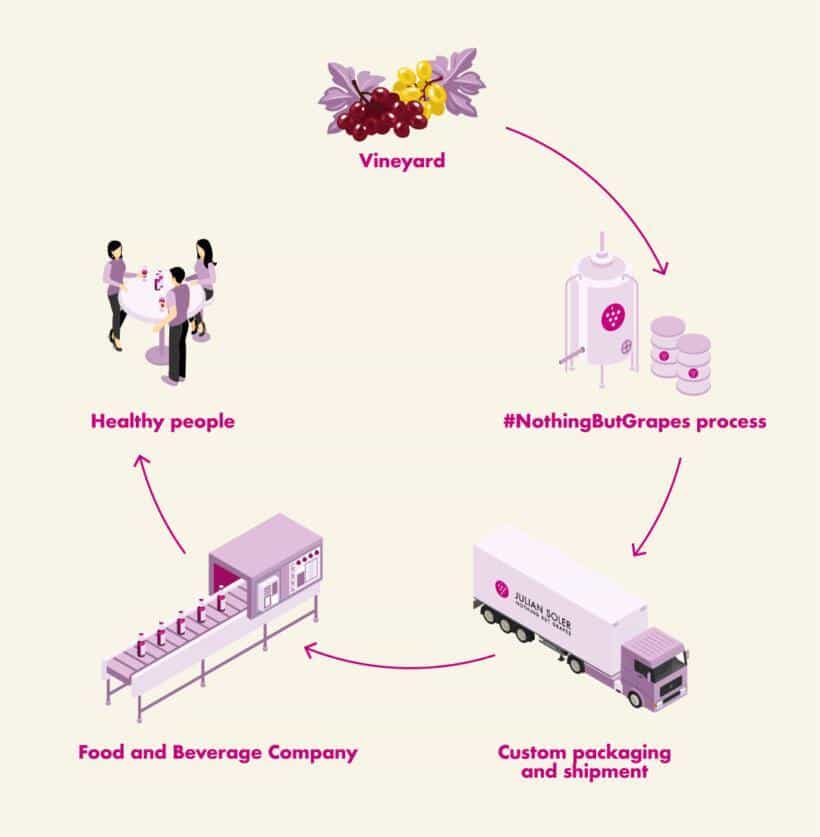

In this post, we explain how we implement traceability of concentrated grape must at Julián Soler, covering the entire production cycle, from the vineyard to delivery to various industries, including food and beverage, among others. We detail the systems, technologies, and records used, as well as the advantages this brings to our customers.

- What does traceability in the agri-food supply chain consist of?

- Traceability of concentrated grape must: Julián Soler process

- How does the traceability of our concentrated must benefit our customers?

What does traceability in the agri-food supply chain consist of?

In the agri-food sector, traceability in the supply chain is the ability to track a food product, ingredient, or agricultural raw material from its origin to its final destination, with detailed and documented monitoring of each stage of the product cycle. This tracking covers everything from cultivation or primary production, through the entire history of processing, transformation, storage, and distribution, to the marketing of the product (export or retail sale) or its use as an ingredient in other foods or beverages. This traceability makes it possible to verify and guarantee the specific characteristics of the product, identify the procedures applied in its planting or industrial processing, provide accurate information to consumers, and analyze and facilitate the withdrawal of a product from the market. It is the way to ensure transparency and food safety throughout the entire chain.

Supply chain traceability can be classified in different ways. Depending on the activity in which a company is engaged (producer, manufacturer, exporter, distributor), it can implement one or another type, or even all of them.

- Backward traceability. Allows the origin of the product to be identified by tracking data from the supplier, farmer, geographical location of cultivation or processing, ingredient batch, etc.

- Internal or process traceability. This focuses on tracking food through all internal management processes at a plant, from the receipt of raw materials, temperatures, and biochemical analysis control during the manufacturing process to the storage of the final product.

- Forward traceability. This involves tracking the finished product along its logistics route to the customer (whether this is an industry that will transform that ingredient, a retail company, or the end consumer).

When it comes to the production of concentrated grape must, traceability is essential for any industrial supplier seeking to guarantee juice quality and food safety, as well as helping client companies to increase consumer confidence.

Traceability of concentrated grape must: Julián Soler process

As producers and exporters of concentrated grape juice, the traceability of our product is a commitment to our customers. This monitoring begins with the preparation of the crop and the harvesting of the grapes. The high quality of the concentrated must, the intensity of its color and flavor, its nutritional profile, and other physical and chemical properties depend on the methodologies and controls we implement in the vineyard; the unique processing we carry out; and the storage and transport conditions we guarantee.

The process at Julián Soler involves the use of digital tracking technologies, constant internal audits, analytical controls, and support for more than 300 local farmers, which has always been our hallmark. Because producing Julián Soler-brand concentrated grape juice is more than just a process… it is art… it is Castilian-La Mancha tradition. A tradition that we bring to more than 60 countries around the world.

Our traceability covers the entire life cycle of concentrated grape must. This involves tracking data on cultivation, transport to the plant, concentration and production methods, analyses to ensure the quality of both the grapes (raw material) and the juice, storage conditions to guarantee the nutritional profile and color of the must, and data from logistics, packaging, and international distribution of the final product. It is traceability from the vineyard to the industry, on any of the five continents.

Let’s take a closer look at what traceability throughout the supply chain entails. Julián Soler:

Traceability in cultivation: guarantee of origin for grapes from Castile-La Mancha

Each batch of concentrated grape must we produce has a story that begins in the land of Castilla-La Mancha, in La Manchuela. We manage a backward traceability system, centralizing data from each phase of cultivation and grape harvesting, from planting, irrigation, growing conditions, degree of ripeness, harvesting, transport to the plant, and unloading.

- We record the data of the vineyard of origin of each batch of grapes received, who is the farmer who cultivates it, the variety planted, and the agronomic treatments applied.

- We collect real-time data on the growing cycle in our own vineyards, such as soil conditions, crop yield, ripeness index, weather patterns, and the evolution of each of the vine’s phenological stages.

- We support farmers from the outset, advising them on best sustainable practices and helping them to ensure that each batch meets the required quality standards. This technical support reinforces our commitment to local producers and guarantees the integrity of the product from the root..

For us, being ambassadors for Castilian-Manchegan grapes means being guarantors, throughout the world, of the quality and authenticity of every drop of concentrated must that is produced and leaves our plant.

Traceability in the production process of concentrated must

When we receive fresh grapes at our facilities, internal traceability begins. Each shipment is registered with a unique batch code that will accompany the product throughout the entire production cycle: obtaining the free-run juice, concentration through controlled evaporation, filtration processes, and final storage. In addition, at each of these stages, we carry out rigorous analytical controls in our laboratory equipped with advanced technologies to evaluate the physical-chemical parameters (acidity, formaldehyde index, conductivity, etc.), microbiological tests, and sensory examinations of our product. This allows us to guarantee the high quality of the must and the characteristics required by the customer, such as Brix degrees and color.

- To maintain traceability, all this data remains linked to the original batch of grapes and is stored centrally in our comprehensive management system. This system incorporates access controls and cybersecurity protocols to guarantee the integrity of the information.

- We have an advanced storage system equipped with cold rooms, freezers, and smart sensors, which guarantees both the preservation of the organoleptic and physical-chemical properties of the concentrated grape juice and the constant monitoring of temperature, humidity, and other key parameters. This data is automatically stored in our information systems. In addition, the unique code corresponding to the batch of grapes used in production is guaranteed to be traceable.

Traceability in transport and distribution

At Julián Soler, backward traceability encompasses the monitoring of the packaging, shipping, and delivery processes of bulk juice to industrial customers. This allows us to guarantee that our customers receive the product in perfect condition, without alterations, and with all the technical and health information they need to integrate the concentrated juice into their own production. In each shipment:

- We package the product aseptically, in a sterile environment, in drums, flexitanks, goodpacks, or refrigerated trucks.

- We accompany the shipment with the product data sheet, batch identification, production dates, logistics documentation, certificates, and quality analyses.

- Transportation is carried out under controlled temperature conditions. To this end, we use advanced tracking technologies for all modes of transport, whether sea, air, or land. For example:

- We integrate continuous monitoring IoT devices that record critical variables such as environmental conditions, temperature, humidity, etc. These systems:

- They are connected to our management systems, allowing us to view, record, and analyze data from any shipment.

- They feature proactive alarms that immediately notify any deviation from the programmed parameters. This ensures maximum safety for our product.

- We integrate continuous monitoring IoT devices that record critical variables such as environmental conditions, temperature, humidity, etc. These systems:

How does the traceability of our concentrated must benefit our customers?

Thanks to our comprehensive traceability system, client companies can trace the origin of the concentrated must back to the specific vineyard in Castilla-La Mancha. The benefits for the industry are as follows:

- Guaranteed food safety.

- Compliance with national and international regulations.

- More agile audit processes.

- Optimization of logistics and inventory management.

- Greater transparency for the end consumer.

We add value to our customers’ entire supply chain thanks to our know-how.

We have been members of SGF International for over 25 years, guaranteeing authenticity and traceability through rigorous audits and analyses.

In addition to various certifications that endorse our food safety systems, such as FSSC 22000, CAAE organic certification, FSA, and SMETA standards, which reflect our commitment to sustainability and social responsibility.

We are your Global Grape Solution Supplier. We help you meet the most demanding safety and quality standards in your industry.

Request more information. We deliver concentrated grape juice wherever you need it, anywhere in the world.

by

by